EFRE-Funding-Projects

European Regional Development Fund

ZME – ZWT – ZWT 2.0 – ZAS

The PHWT is pleased to have received financial support from the European Regional Development Fund (ERDF)! In addition to other co-financing, these could be used for the establishment of the Centre for Materials and Technology (ZWT) as well as for research equipment in the Centre for Mechatronics and Electrical Engineering (ZME) in Diepholz. Furthermore, the expansion of the Centre for Materials and Technology (ZWT) to include the research areas “Microplastic Analysis” and “Plastics Recycling” (ZWT 2.0) and the establishment of the Centre for Applied Simulation Technology (ZAS) will be made possible.

Zentrum für Mechatronik und Elektrotechnik (ZME)

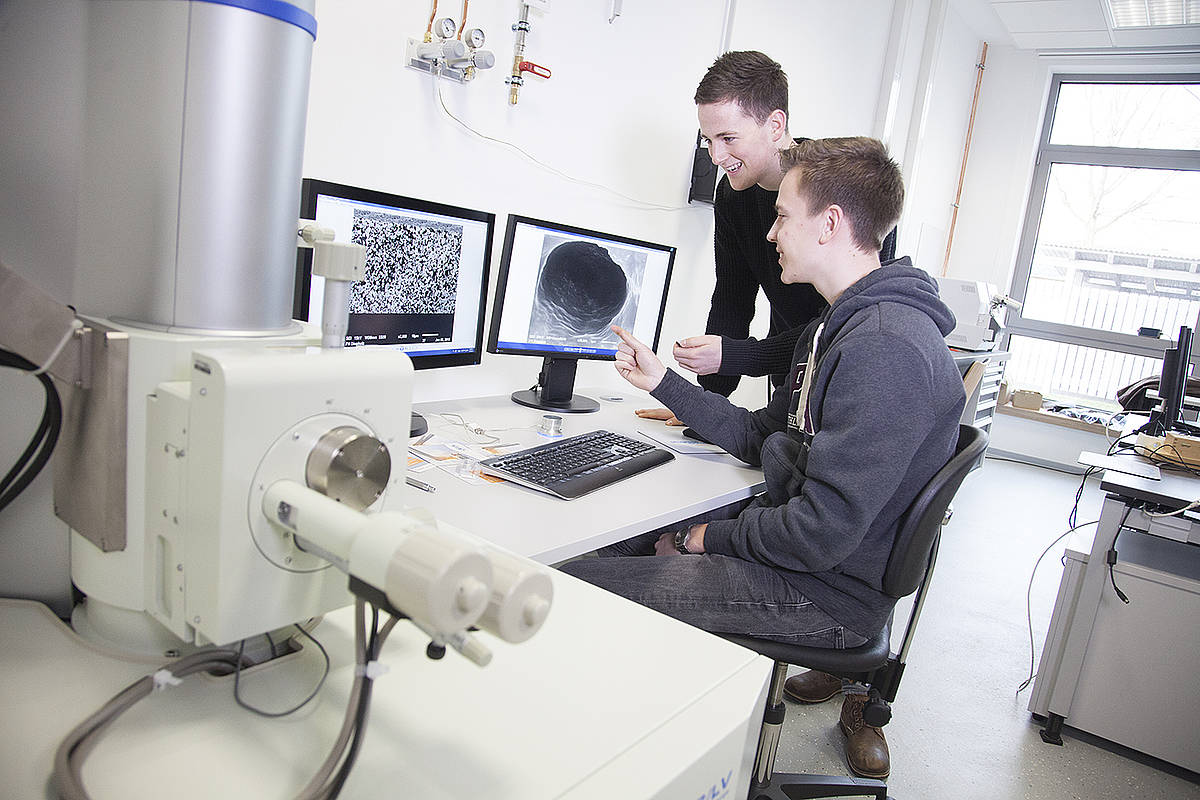

The ZME is available to students of the Private University of Applied Sciences Vechta/Diepholz (PHWT) and companies with its modern facilities, new lecture rooms and numerous first-class equipped laboratories in the field of materials and production engineering.

The engineering courses of study at the PHWT have been given additional outstanding opportunities by the ZME to significantly expand their activities in teaching and applied research.

The ZME serves as a cooperation partner for companies in applied research and development. This gives them access to expertise and technology that is not available in-house.

The excellent research infrastructure of the ZME is oriented towards questions from the fields of modern engineering sciences.

Research area “Smart Systems

Laboratory: Electronics production, soldering stations, optical inspection

Laboratory: Development and testing

Laboratory: (human-machine interaction)

Laboratory: Health monitoring

Research area “Autonomous Mobile Systems

Laboratory: Battery management systems

Laboratory: Automated Driving / Precision Farming

Research Area “Alternative Drive Systems

Laboratory: Test bench / Electrical machines

The engineering-qualified laboratory personnel are also available for corresponding services. Please do not hesitate to contact us.

Zentrum für Werkstoffe und Technik (ZWT)

The Centre for Materials and Technology (ZWT) is available to students of the Private University of Applied Sciences Vechta/Diepholz (PHWT) and companies with its modern facilities, new lecture rooms and numerous first-class equipped laboratories in the field of materials and manufacturing technology.

The engineering courses of study at the PHWT have been given additional outstanding opportunities by the ZWT to significantly expand their activities in teaching and applied research.

The ZWT serves as a cooperation partner for companies in applied research and development. This gives them access to expertise and technology that is not available in-house.

Research areas microplastics analysis and plastics recycling (ZWT 2.0)

The Private Hochschule für Wirtschaft und Technik (PHWT) is a state-recognised and privately financed university with dual accredited study programmes and two locations in Vechta and Diepholz.

The PHWT can be traced back to a private initiative by representatives of the business community who, more than 30 years ago, set themselves the goal of opening up an outstanding, practice-oriented qualification programme for young people in the region of northwest Germany. They joined forces to form the Berufsakademie Oldenburger Münsterland e. V. association, which currently has around 180 member companies. Also with a high level of private commitment, DR. JÜRGEN UND IRMGARD ULDERUP STIFTUNG is also committed to promoting education in the region. It has been financing the mechanical engineering course at the PHWT since 1995. Today, the PHWT is run by the non-profit Private Hochschule für Wirtschaft und Technik gGmbH (Private University of Applied Sciences) with currently seven shareholders, the PHWT Unternehmens- und Mitgliederverbund e. V. (PHWT Association of Companies and Members). (PHWT e.V.), the DR. JÜRGEN UND IRMGARD ULDERUP STIFTUNG, the HARTING Stiftung & Co. KG, the district of Diepholz, the city of Diepholz, the district of Vechta and the city of Vechta.

In addition to the topics of dual studies and qualification, the PHWT would also like to position itself more strongly as a research and development institution in Lower Saxony. With the Centre for Materials and Technology (ZWT) and the Centre for Mechatronics and Electrical Engineering (ZME), two institutes have already been established here that are closely involved with the current application-related R&D issues of the regional economy. The spatial focus of activities here is on the districts of Vechta and Diepholz as well as the neighbouring regional authorities, where the provision of R&D facilities is otherwise rather weak.

The goal is now to strengthen and expand the PHWT’s R&D capacities through the ZWT 2.0 project. The design of the laboratories is derived from the professional competences of the PHWT professors and is at the same time oriented towards current research topics and development issues of regional companies.

Zentrum für angewandte Simulationstechnik (ZAS)

With funding from the European Union and with the Centre for Materials and Technology (ZWT) and the Centre for Mechatronics and Electrical Engineering (ZME), two institutes have already been established here that are closely involved with the current application-related R&D issues of the regional economy. However, the activities of both centres are primarily experimentally or empirically oriented. The continuously growing use of computer simulations in product development as an offer for research and further education for regional companies could only be served by the PHWT in isolated cases so far.

Computer simulation is indispensable for product development, primarily for reasons of time and cost, as well as in some cases for lack of testable products or components. It can be expected that the use of simulation techniques will increase more and more in the context of increasing digitalisation. This applies all the more where product and functional complexity increase and technical feasibility limits are to be reached. This is not possible through predominantly experimental or empirical methods, as the effort involved would be disproportionately high.

Therefore, the PHWT’s capacities in the field of computer simulations are to be expanded within the framework of a Centre for Applied Simulation (ZAS) and its competences in computer-aided product development are to be made accessible to SMEs and craft enterprises in the region.

Subsidy project to increase the proportion of recycled material

“CoMelt” – Development of a new mixing unit for use in the injection moulding process for mixing and homogenising a melt of recyclate with the melt of a specified material grade (virgin material).

In 2018, 29.1 million tonnes of collected plastic waste was available on the European recycling market, of which 42.6% was thermally recycled and not reused as material. Just under 25% was sent to landfill. It is striking here that in certain sectors, such as automotive and electrical/electronic, almost no recyclates are used, especially in the production of technical components. In 2017, only 4% of the plastics used in these sectors were recycled. The most critical obstacles why recyclates are not increasingly used here include:

No individual homogenisation of the different grades of STS.

Limited recyclate content

Regrind and virgin material need similar property profile, otherwise they cannot be mixed

Low component qualities, as component properties are heterogeneous

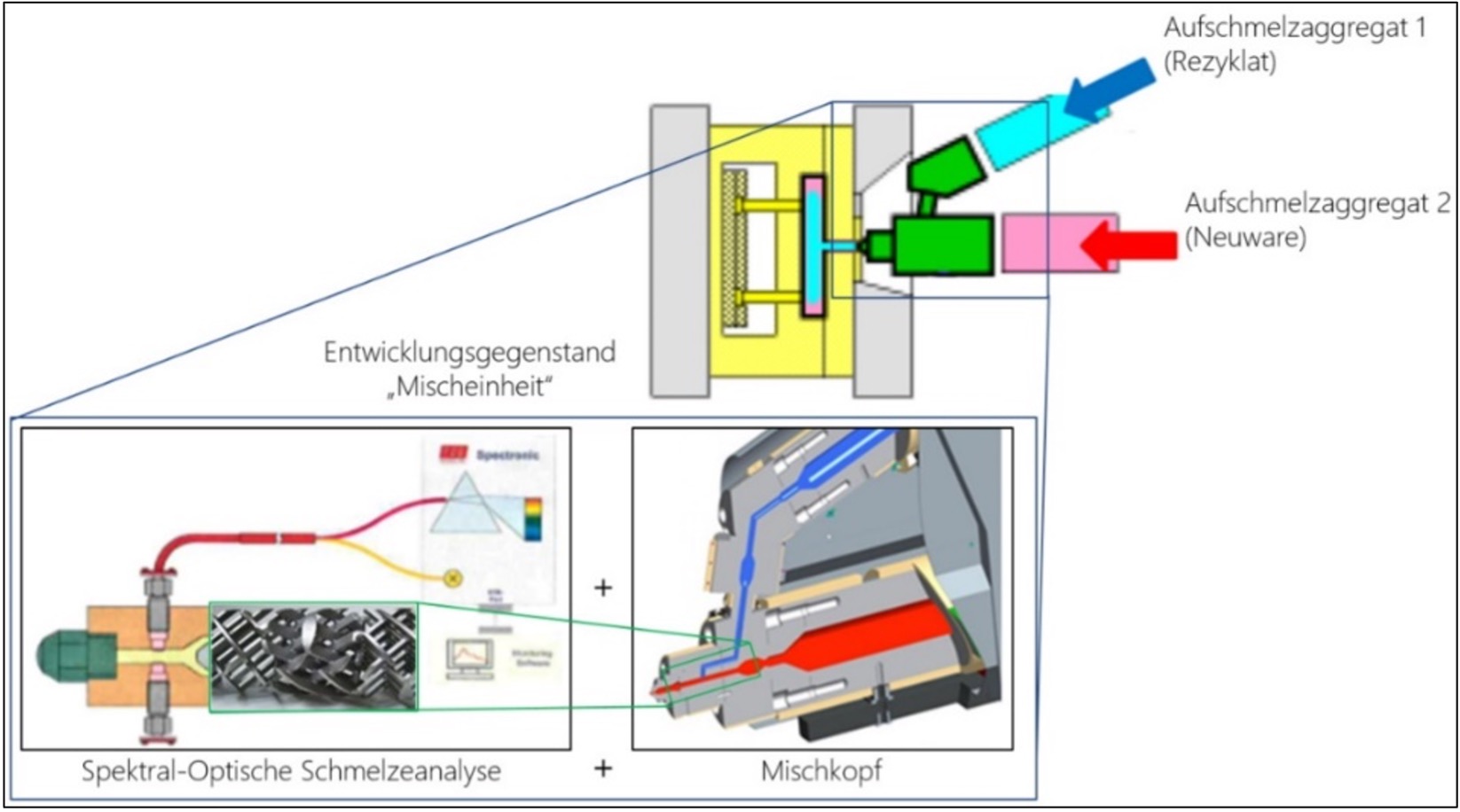

Presentation of the planned new development of a mixing unit (CoMelt)

The aim of the cooperation project between the company Merkutec and the PHWT, which is funded by the NBank’s innovation programme, is to develop a process and a product (mixing unit) with which the recyclate content in technical products in the injection moulding process can be significantly increased. Through a better and more individual homogenisation of the two different material qualities (virgin material-recycled material) due to the separate melting, a more constant and simpler processing of the regrind in the injection moulding production is to be achieved with a simultaneous increase of the regrind proportion in the mixture (virgin material-recycled material), see the following figure.

By measuring the melt quality by means of spectral-optical analysis, the quality of the entire process and thus also the component quality becomes measurable, controllable and adjustable, which eliminates the obstacles described above. In the case of existing material recycling, this subsequently enables a reduced processing effort: the recyclate can be produced more coarsely, more dustily, more simply and thus more cheaply and transferred back into processing. The possibility for economic use in the series production of technical components would thus be given.

The project has been approved and will be realised from 01.03.2021 to 30.06.2022. The project is being managed by Merkutec, the PHWT is integrated as a cooperating university, and the project idea was developed at a meeting of the Recompound project group of the ZWT e. V. research association.